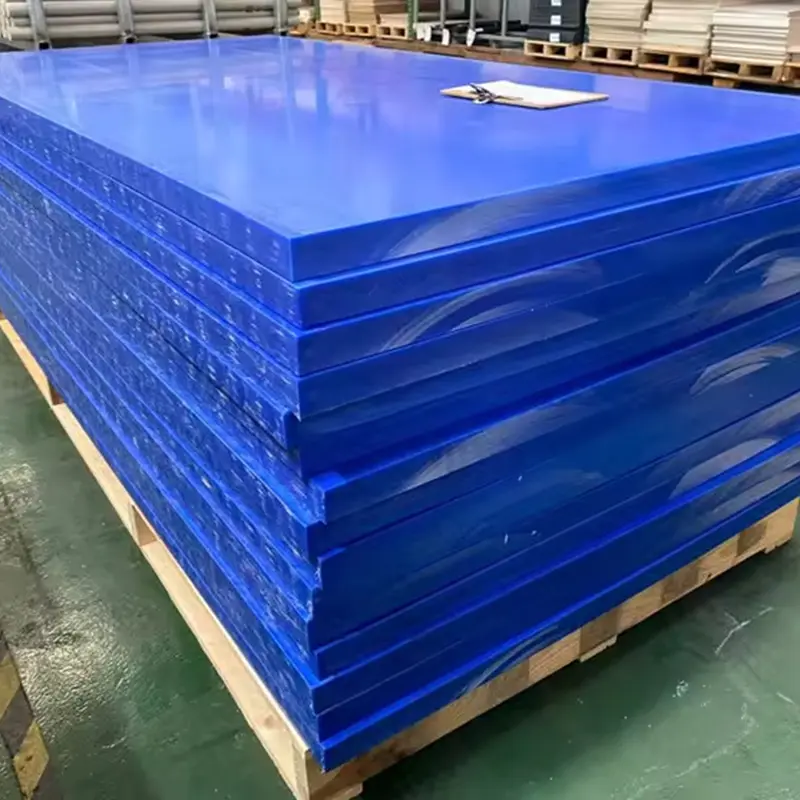

Ultra-high molecular weight polyethylene, abbreviated as UHMWPE, is a unique thermoplastic engineering plastic that has garnered widespread attention due to its outstanding physical properties and diverse application areas. With a molecular weight typically exceeding one million, UHMWPE possesses exceptional characteristics such as high abrasion resistance, impact strength, self-lubrication, and chemical corrosion resistance. These attributes make UHMWPE an ideal material for manufacturing anti-pressure, anti-slip, and wear-resistant sliders.

In industrial production, sliders, as crucial mechanical components, find extensive use in various equipment and machinery. The primary function of sliders is to withstand pressure and friction, necessitating excellent wear resistance and compressive performance. Ultra-high molecular weight polyethylene stands out as one of the ideal materials possessing these characteristics.

- Firstly, UHMWPE exhibits remarkable wear resistance. In high-speed, high-load working environments, UHMWPE outperforms conventional metallic materials in terms of wear resistance. This is attributed to its tightly packed and flexible molecular chain structure, which prevents the material surface from easily scratching or wearing under friction. Consequently, sliders manufactured from UHMWPE maintain a lower wear rate over prolonged usage periods, thereby extending the equipment’s lifespan.

- Secondly, UHMWPE demonstrates excellent compressive performance. Under high-pressure conditions, UHMWPE maintains good elasticity and stability, resisting deformation or rupture. This stability ensures that UHMWPE sliders remain performance-stable even under heavy pressure, guaranteeing the normal operation of equipment.

Moreover, UHMWPE possesses self-lubricating properties. During friction, a lubricating film forms on the surface of UHMWPE, reducing the friction coefficient and minimizing energy loss. This characteristic facilitates smoother sliding of UHMWPE sliders, reducing frictional wear and enhancing equipment efficiency.

In addition to the aforementioned advantages, UHMWPE can be tailored to meet specific application requirements. Through modification processes such as adding fillers or reinforcing agents, UHMWPE’s performance can be enhanced according to different working environments and usage demands. Furthermore, customization of UHMWPE sliders based on specific size and shape requirements can cater to the needs of various equipment.

In summary, ultra-high molecular weight polyethylene, as a unique thermoplastic engineering plastic, possesses significant advantages in manufacturing anti-pressure, anti-slip, and wear-resistant sliders. Its outstanding wear resistance, compressive strength, and self-lubrication make UHMWPE sliders essential components in industrial production. Through on-demand customization, sliders meeting diverse requirements can be produced, providing stable and reliable support for various equipment and machinery. With technological advancements and industrial development, UHMWPE sliders are poised to find broader applications and promotion across different fields.

.

YaKai Plastics

YaKai Plastics

HelloPlease log in