UHMWPE Chain Guides

Durable, High-Performance, Smooth, and Reliable Operation

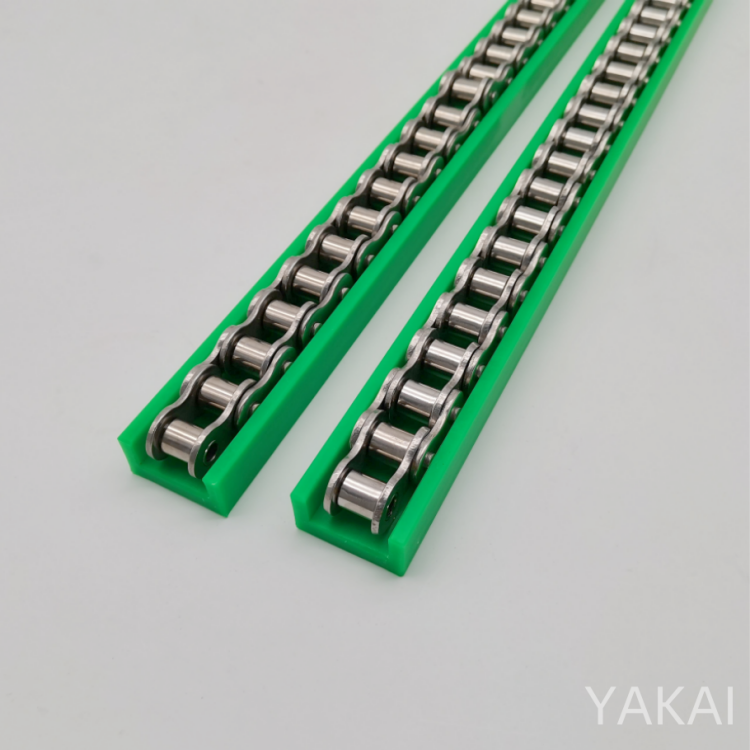

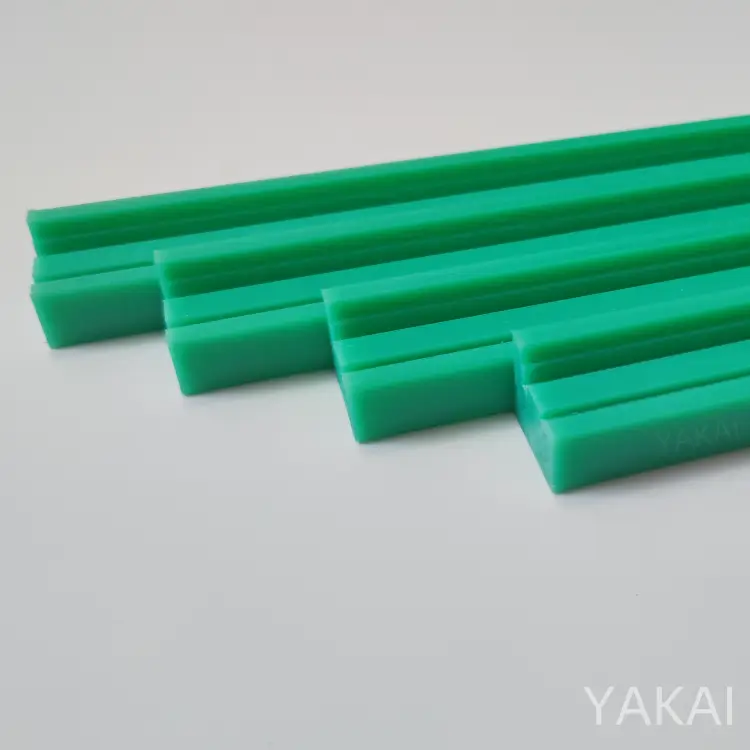

Our UHMWPE Chain Guides offer exceptional wear resistance, low friction, and long-lasting performance, making them ideal for demanding industrial applications. Precision-engineered to minimize chain wear and reduce maintenance costs, they ensure efficient and quiet operation.

UHMWPE Liners Information

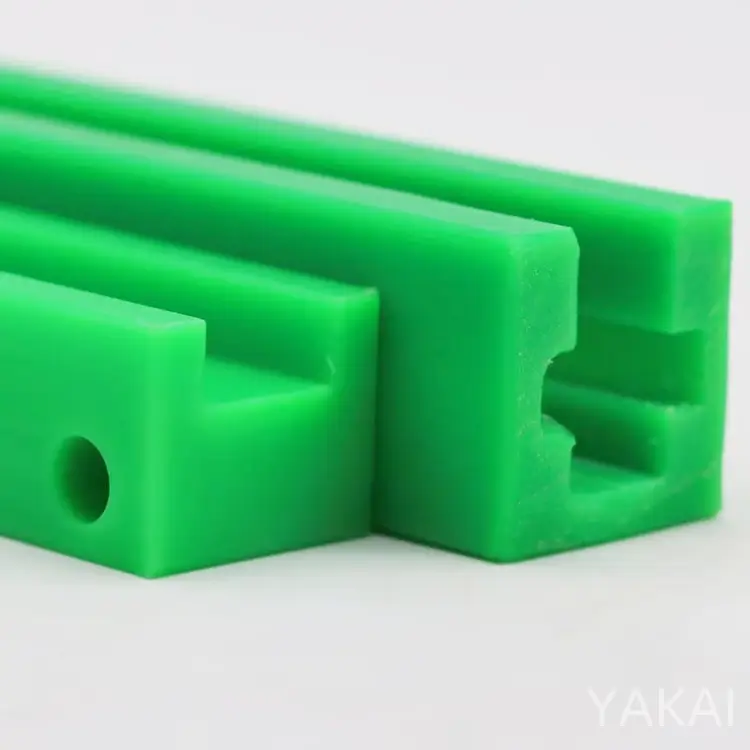

UHMWPE (Ultra-High Molecular Weight Polyethylene) chain guides are high-performance components designed to precisely direct and guide chain movement in various machinery. They are commonly used in industrial machines, transportation systems, and equipment to ensure smooth and efficient chain operation. With exceptional wear resistance, low friction, and outstanding corrosion resistance, UHMWPE chain guides are widely used in applications requiring high reliability and long-term stability.

Applications of UHMWPE Liners

Industrial Machinery: Used in automated production lines, packaging equipment, conveyor systems, and material handling machinery, ensuring smooth chain operation and minimizing downtime.

Food & Pharmaceutical Processing: UHMWPE chain guides are widely used in food and pharmaceutical processing equipment due to their excellent hygiene properties, resistance to chemicals, and ability to withstand frequent cleaning.

UHMWPE Liners' Key Features:

- Low Coefficient of Friction: UHMWPE’s extremely low friction reduces wear between the chain and guide, extending the lifespan of both components.

- High Abrasion Resistance: UHMWPE withstands repeated friction in high-cycle environments, ensuring long-term, stable operation.

- Self-Lubricating: With self-lubricating properties, UHMWPE reduces reliance on external lubricants, lowering maintenance costs and complexity.

- Corrosion Resistance: UHMWPE’s excellent resistance to chemicals and moisture makes it ideal for harsh environments like food processing, chemical handling, and marine applications.

- Lightweight: Compared to metals, UHMWPE is lightweight, making it ideal for applications where weight is a critical factor.

- Noise Reduction: UHMWPE chain guides produce less noise than metal alternatives, helping to reduce noise pollution in working environments.

Why Choose UHMWPE Chain Guides?

Compared to traditional metals or other plastic materials, UHMWPE chain guides offer many significant advantages. First, UHMWPE provides an extremely low coefficient of friction, which effectively reduces wear between the chain and the guide, extending both the chain and the guide’s lifespan. Additionally, the material is lightweight, making it ideal for applications that require weight reduction. Furthermore, UHMWPE offers excellent abrasion and chemical resistance, ensuring stable performance in harsh environments and reducing maintenance costs.

FAQ

Why Choose UHMWPE Over Metal and Other Plastic Materials for Chain Guides?

Metal Materials (e.g., Steel, Aluminum): While metal chain guides offer higher strength than UHMWPE, metals are prone to rust and have higher friction, leading to more wear. UHMWPE outperforms metals in corrosion resistance, wear resistance, and noise reduction, and does not require regular lubrication.

Other Plastic Materials (e.g., PVC, Nylon): While other plastics may provide some performance benefits, UHMWPE stands out with its exceptionally high molecular weight and superior abrasion resistance, offering better durability and self-lubrication compared to these common plastic materials.

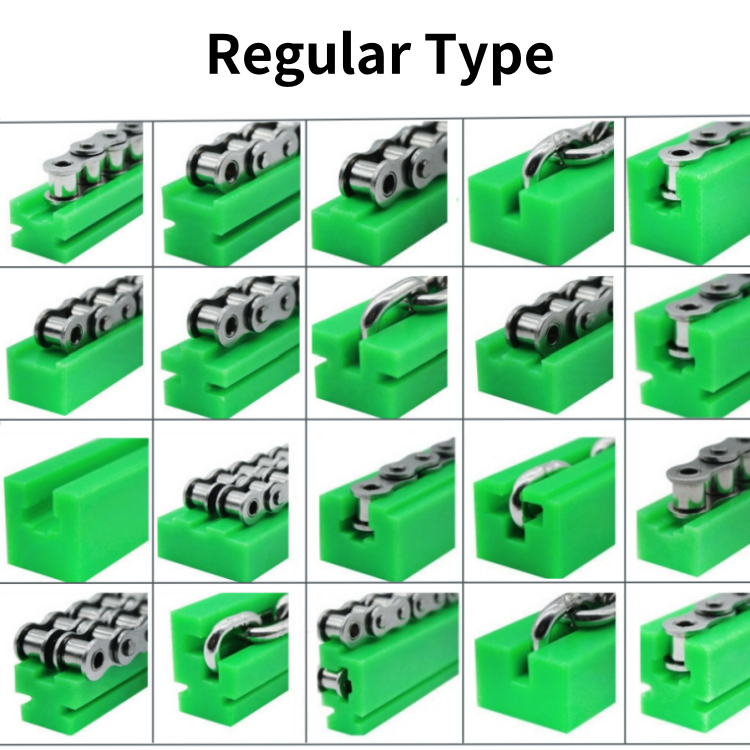

What are the regular types of UHMWPE Chain Guide Rail?