High-capacity crane pumps, crane leg mats, rubber pad blocks, and polyethylene materials.

578Application of Ultra-High Molecular Weight Polyethylene

View detailsSearch the whole station HDPE Sheet

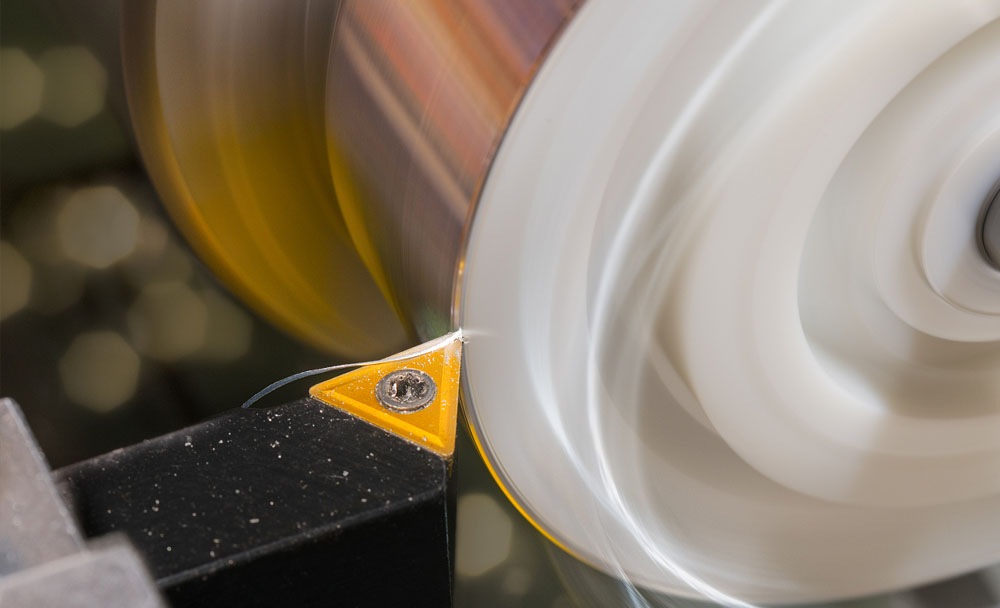

Plastic processing is easy to appear edges, and sharp angles will affect the quality and efficiency of processing and increase the processing difficulty. Therefore, parts should avoid internal edges, circular arcs, and other smooth shape.

The cutting direction will affect the part’s surface quality and machining difficulty. The design of parts should be according to the nature of plastic materials and processing requirements to choose the appropriate cutting direction, as far as possible, to avoid reverse or oblique cutting.

Plastic materials shrink during cooling, so you need to design parts with a shrinkage rate in mind and design with an appropriate allowance for subsequent processing or assembly.

Before CNC machining, we must determine the process flow, including machine type, tool type, processing sequence, etc. When designing parts, the processing sequence should be considered according to the process flow to ensure the smooth processing of parts and reduce processing errors.

In CNC machining, excessive cutting should be avoided, leading to accelerated tool wear and affecting the quality and efficiency of machining. In the design of parts, one should avoid too much depth or too small a cutting interval to reduce tool wear and machining errors.

Application of Ultra-High Molecular Weight Polyethylene

View detailsAging-resistant high-density HDPE board, impact-resistant polyethylene board, corrosion-resistant and wear-resistant PE plastic board

View detailsWith the rapid development of modern industry, the application of polymer materials is becoming increasingly widespread in numerous fields. Among them, high-density polyethylene (HDPE), as an excellent engineering plastic, is widely utilized in v...

View detailsdock fender panels

View detailsWe use cookies to help improve our services, make personal offers, and enhance your experience. If you do not accept optional cookies below, your experience may be affected. If you want to know more, please read the Cookie Policy

Privacy Policy

HelloPlease log in