The anti-pressure and ultra-wear-resistant polyethylene crane outrigger mat—An indispensable industrial accessory

377Application of Ultra-High Molecular Weight Polyethylene

View detailsSearch the whole station HDPE Sheet

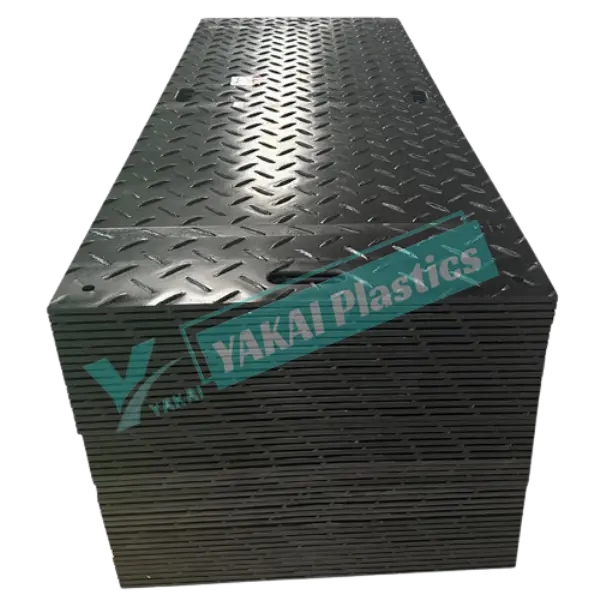

Among the numerous engineering materials, traditional materials such as polyethylene pavement mats, plywood, and fiberglass have long played significant roles. However, with the advancement of technology and increasing engineering demands, these traditional materials have proven inadequate in certain applications. At such times, a new type of material emerges, serving as a superior alternative to these traditional materials due to its outstanding characteristics such as excellent slip resistance, dimensional stability, rot resistance, and absence of cracks or delamination.

During the design and manufacturing process of this new type of material, various complex environmental conditions encountered in engineering practice are fully considered. Regardless of high or low temperatures, wet or dry conditions, it maintains stable performance without deformation or rotting. This is thanks to its unique material structure and manufacturing process, enabling it to maintain excellent performance under various extreme conditions.

Slip resistance is another major highlight of this new type of material. Whether on flat roads or rugged terrain, it provides outstanding slip resistance, effectively reducing safety incidents caused by sliding. This characteristic fosters extensive application prospects in fields such as transportation and construction.

Furthermore, this new type of material exhibits excellent crack resistance and resistance to delamination. During use, it does not develop cracks or delamination due to external impact or prolonged usage. This greatly extends the material’s service life, reduces maintenance costs, and delivers tangible economic benefits to users.

Compared to traditional materials like polyethylene pavement mats, plywood, and fiberglass, this new type of material undoubtedly offers greater advantages. It not only meets various complex engineering requirements but also demonstrates significant improvements in performance and service life. With the advancement of technology and increasing demands for material performance, this new type of material will undoubtedly play a more important role in future engineering fields.

In conclusion, this new type of material, with its superior characteristics such as slip resistance, dimensional stability, rot resistance, and absence of cracks or delamination, serves as an ideal substitute for traditional materials. Its emergence not only meets the high demands for material performance in engineering practice but also brings new opportunities and challenges to various industries’ development. We have every reason to believe that in the future, this new type of material will play a more significant role in advancing human society, contributing to progress.

Moreover, the widespread application of this new type of material will also drive the development and innovation of related industrial chains. From raw material extraction to process improvement and product application and promotion, a complete industrial chain system will be formed. This will bring more business opportunities and development space to relevant enterprises and industries, promoting economic prosperity and social progress.

Of course, the emergence of any new type of material requires rigorous testing and verification to ensure its safety and reliability in practical applications. This requires joint efforts from researchers, engineers, and industry experts to conduct in-depth research and analysis on this new type of material, continuously improving its performance and application scope. Only in this way can we fully leverage the advantages of this new type of material, bringing more convenience and well-being to human production and life.

In summary, this new type of material, with its superior characteristics such as slip resistance, dimensional stability, rot resistance, and absence of cracks or delamination, brings a fresh alternative to traditional materials. Its emergence will drive innovative development in the engineering field and promote the prosperity and progress of related industrial chains. We have every reason to believe that in the future, this new type of material will make a more significant contribution to the development of human society.

Application of Ultra-High Molecular Weight Polyethylene

View detailsUltra-high molecular weight polyethylene scraper is a specialized industrial product made of a particular material, which has garnered widespread attention and application in the industrial sector due to its excellent performance and diverse uses...

View detailsPE plastic ground protection mats are widely used as temporary or permanent paving materials in places like coal mines, factories, and warehouses. Compared to traditional concrete or stone slabs, PE plastic ground protection mats have many advant...

View detailsI. Applications of Ultra-high Molecular Weight Polyethylene slidersII. Functions and Features of Ultra-high Molecular Weight Polyethylene sliders Ultra-high molecular weight polyethylene (UHMWPE) slider is a high-performance wear-resistant compone...

View detailsWe use cookies to help improve our services, make personal offers, and enhance your experience. If you do not accept optional cookies below, your experience may be affected. If you want to know more, please read the Cookie Policy

Privacy Policy

HelloPlease log in